Food safety is a concern that no produce processor can afford to overlook.

Ensuring that your operations abide by the requisite legislation and guidelines is both a legal obligation and a firm assurance to your customers.

Failure to comply with these regulations could lead to grave repercussions, inflicting both financial penalties and damage to your reputation.

The task of achieving and maintaining compliance can be complex and challenging.

This blog will provide guidance to ease this process, signaling the pivotal role of compliance in the produce processing industry.

We will explore useful and practical tips designed specifically for produce processors.

Contents

- Food Safety Compliance Tips For Produce Processors

- 1. Regularly sanitize equipment and processing machinery

- 2. Prohibit Sick Employees from Handling Produce

- 3. Implement Rigorous Hand-Washing Policies

- 4. Maintain Proper Cold Storage Temperatures

- 5. Ensure pest control activities regularly.

- 6. Use Approved Pesticides Following Manufacturer Guidelines

- 7. Routinely Train Staff in Food Safety

- 8. Regularly Evaluate Supplier Food Safety Compliance

- 9. Use Clean, Suitable Packaging Materials

- 10. Conduct periodic food safety audits.

- The Bottom Line

Food Safety Compliance Tips For Produce Processors

1. Regularly sanitize equipment and processing machinery

The role of sanitization in the context of produce processing cannot be overstated.

It is a crucial practice that ensures the safety and quality of food.

Produce processors have a responsibility to uphold high hygiene standards in their workstations.

Cleaning should be done regularly and comprehensively to avoid contamination.

This is especially true when it comes to the equipment and processing machinery used.

Regular sanitization of equipment and machinery can dramatically reduce the risk of foodborne illnesses associated with contaminated produce.

You should establish a regular cleaning schedule to ensure that equipment and machinery are always sanitized before and after use.

This routine may include daily, weekly, or monthly cleanups depending on the nature of the machinery.

Machinery should be dismantled where possible to ensure all components are thoroughly cleaned.

Sanitizing solutions approved by food safety authorities should be used in the cleaning process.

Proper cleaning techniques need to be employed to ensure all dirt and microbial residue are cleared off.

Ideally, sanitization should be a multi-step process including pre-wash, main wash, rinse, sanitize, and dry.

The sanitization process should be evaluated regularly and improved where necessary to ensure it remains effective.

Overall, regular sanitization of equipment and processing machinery is not just a regulatory requirement, it is a crucial part of maintaining the integrity of the food supply chain.

Produce processors that diligently maintain the cleanliness of their equipment will enjoy better business reputations, avoid costly food recalls and enhance the safety and quality of their products.

Remember, sanitation is not a one-off task, it should be an integral part of the production process.

2. Prohibit Sick Employees from Handling Produce

In the food processing industry, ensuring food safety and hygiene is of paramount importance. One crucial step towards achieving this is to prohibit sick employees from handling produce.

Sick employees constitute a major risk in transmitting diseases and infections, which can contaminate the fruits and vegetables being processed. This risk is even higher if the employees are suffering from a foodborne disease.

Strong policies should be put in place to prevent this kind of situation. It should be clearly communicated to the employees that they should not report to work if they are feeling unwell. This approach helps to prioritize the consumer’s health and safety.

Leave policies should also be adjusted to discourage sick employees from coming to work. Offering paid sick leave is an effective way to ensure employees stay at home when they are unwell, reducing the risk of contamination.

Employees should be trained to recognize the symptoms of foodborne illnesses like nausea, vomiting, diarrhea, and fever, among others. When they see these symptoms in themselves or their colleagues, they should report to the management immediately.

Utilizing health screening and regular medical checkups is another proactive way to mitigate the risks associated with sick employees. These checkups can identify potential health issues before it becomes a problem.

Besides physical health, attention should also be paid to employees’ mental health. An employee grappling with stress or mental health issues can also inadvertently compromise food safety.

Preventing sick employees from handling produce is not only critical in maintaining a safe food production process, but it also plays a significant role in the company’s public perception. A single outbreak of illness traced back to your processed produce can be devastating to the brand’s reputation.

This is why it is essential to cultivate a culture that prizes transparency and responsibility in the organization. Encourage employees to take the initiative and responsibility to stay home when unwell to safeguard the health of consumers ultimately.

It is also important to have a well-documented protocol in place in case a sick employee handles food. Such a contingency plan can help minimize damage by quickly isolating and addressing the affected batch of produce.

In summary, keeping sick employees away from handling produce requires a robust system, including proactive health checks, well-articulated policies, continuous training, and an inclusive and empathetic work culture. Always remember, the goal is not just to produce safe foods, but also to ensure a healthy and supportive work environment for your employees.

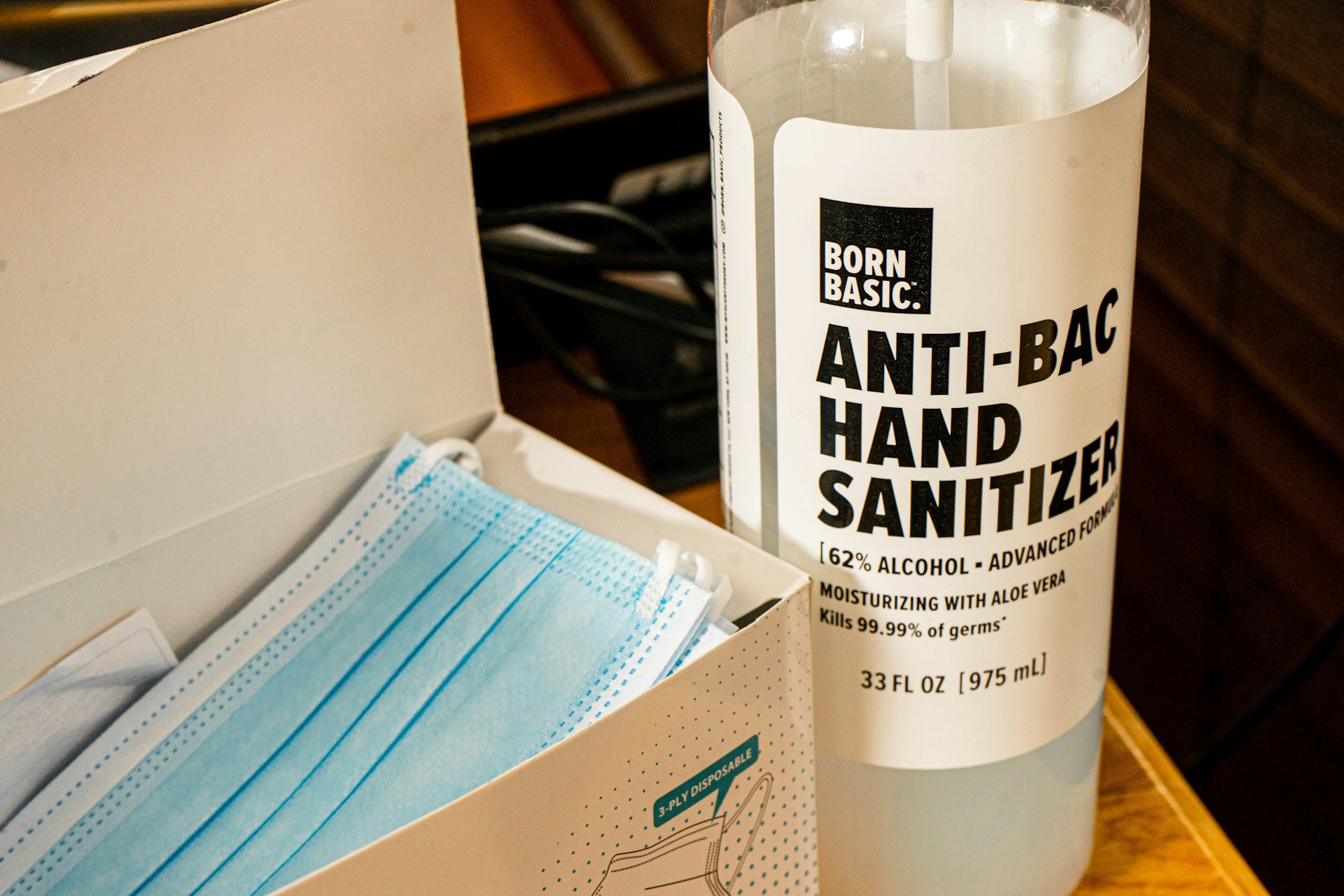

3. Implement Rigorous Hand-Washing Policies

The importance of maintaining strict hand-washing practices within the food processing environment cannot be overstated.

Produce processors must ensure that all employees understand the essential role hand hygiene plays in preventing food-borne illnesses.

It is necessary to establish hand-washing stations in every part of the processing plant where workers handle food directly.

These stations should be well-equipped with antibacterial soap, warm running water and disposable paper towels for drying hands.

The use of non-contact devices, such as automatic soap dispensers and hand dryers, can further minimize contamination risks.

A proper hand-washing technique should be demonstrated and emphasized during training sessions.

Effective hand-washing involves thoroughly scrubbing hands with soap for at least 20 seconds, paying special attention to areas such as under the nails, between the fingers and the back of the hands.

Hand-washing should be mandatory before commencing work, after using the restroom, after breaks, and after any potential contamination event.

Furthermore, management should monitor compliance with these policies on an ongoing basis and enforce strict penalties for non-compliance.

Periodic reminders about the importance of hand-washing, perhaps through posters, emails, or briefings, can be useful in keeping this crucial safety step foremost in employees’ minds.

Additionally, integrating hand hygiene into the company’s culture can lead to better acceptance and adherence among employees.

It may also be beneficial to use bacterial hand swabs as a tool to assess the effectiveness of your hand-washing program.

This measure involves testing the hands of employees after they have completed the hand-washing process to check for residual bacteria.

Data from these tests can help identify where improvements can be made in hand-washing methods.

In summary, a rigorous hand-washing policy is key in maintaining food safety in the processing environment.

By implementing such a policy, produce processors are taking a significant step towards ensuring the production of safe and high-quality produce.

4. Maintain Proper Cold Storage Temperatures

One critical aspect of ensuring food safety compliance in produce processing is the maintenance of proper cold storage temperatures.

The recommended storage temperature for most fruits and vegetables ranges from 0 to 10 degrees Celsius.

Utilizing accurate temperature-checking equipment, such as thermometers, allows for consistent checks to ensure the required temperature is maintained.

To ensure efficient cooling, all produce should be spread out evenly and should not be overloaded in the cold storage facilities.

Constant assessment and prompt response to any fluctuation in temperature guarantee the quality and safety of the produce.

Gauging temperature at various points within the storage area is crucial as there might be potential ‘hot spots’ where temperature control isn’t effective.

Regular maintenance of cold storage facilities and equipment is important to prevent any operational issues that could jeopardize temperature control.

Proper insulation and sealing of storage areas can prevent air leaks, thus optimizing cooling efficiency.

Produce should be stored as soon as possible after harvesting to reduce exposure to higher temperatures and decrease the risk of bacteria growth.

Employing a first-in, first-out (FIFO) policy reduces the chances of storage-related spoilage.

Training employees on the importance of temperature control and how to manage the storage environment can encourage vigilance and understanding.

Immediate intervention and rectification of any issues related to temperature control form the greatest line of defense in food safety.

Any deviation from the set storage temperature should be thoroughly investigated, and solutions should be applied to avoid repeating the same issue.

Lastly, record-keeping is of utmost importance in maintaining proper storage temperatures; it provides necessary insights and can be useful for regulatory compliance.

With the right processes and equipment, maintaining proper cold storage temperatures may not only safeguard against food safety risks but also play a significant role in ensuring product quality.

5. Ensure pest control activities regularly.

Ensuring regular pest control activities is an integral part of maintaining food safety in the produce processing industry.

Pests not only pose a risk of contaminating the food items, but also of spreading harmful diseases.

As such, it is crucial for produce processors to have a comprehensive and long-term pest control strategy in place.

Pests can have severe implications on the hygiene standards and overall quality of the products being processed.

Pest infestations in the processing facility can lead to significant business losses because of the potential for food contamination.

There are myriad pests that can invade a food processing facility, such as rats, cockroaches, flies, and ants, each of which can cause different types of contamination.

Produce processors have to regularly monitor and review their pest control measures to ensure their effectiveness.

It is not enough to merely react to a pest infestation; prevention is always the most effective approach.

Regular pest control audits should be conducted, and modifications to the strategies should be made based on the audit findings.

The pest control measures should be holistic, involving not just the use of pesticides, but also cleanliness and hygiene of the facility.

Proper waste management and disposal is another key aspect of a successful pest control strategy.

Documentation of the pest control activities is also crucial to provide evidence of compliance with food safety regulations.

Lastly, the pest control measures put in place should be environmentally responsible and safe for the employees.

To aid in comprehensive pest control, processors can work with professional pest management companies experienced in dealing with food processing facilities.

Ultimately, by ensuring regular pest control activities, produce processors can significantly uphold and enhance their food safety standards.

6. Use Approved Pesticides Following Manufacturer Guidelines

In the realm of food safety compliance for produce processors, the judicious and proper use of approved pesticides is a very crucial aspect.

These pesticides, when handled and applied correctly, play a critical role in preventing unwanted insects and diseases from damaging our food supply.

It is, however, not enough to simply use these products – they must be used according to the manufacturer’s guidelines to ensure safety and effectiveness.

In fact, failing to comply with these guidelines could lead to regulatory violations, which could have dire consequences for the business and its consumers.

The manufacturer’s guidelines provide detailed instructions on when and how to use these products – ignoring them is not just irresponsible, it’s downright dangerous.

They include precise recommendations on the ideal time to spray, the required protective wear, the right dosage, and important safeguards to prevent contamination of groundwater, among others.

Moreover, by using only approved pesticides, processors are showing their commitment to maintaining high safety standards and ensuring that the produce provided to consumers is healthy and safe.

Yet, it’s also important to remember that not all pests require chemical pesticides. There are some natural methods to control pests, such as the use of beneficial insects.

Pesticide manufacturers also insist on the critical importance of eminent staff training and education in safe handling and application practices.

This helps to ensure that all staff members understand the potential risks associated with these substances and how to avoid them.

Furthermore, it eliminates the risk of accidental over-application, which could lead to pesticide residues showing up in the final product, potentially putting the end consumer’s health at risk.

Keeping this in mind, it’s also worth noting that the choice of pesticides should always be made with care.

The incorrect usage or selection of a pesticide can be a direct violation of food safety regulations and might lead to severe repercussions.

Therefore, it’s advisable for produce processors to consult a pest management professional or a pesticide agent to select the most suitable and approved pesticide for their specific needs.

Remember, safety is the ultimate goal here and ensuring that pesticides are used correctly not only maintains the health of the consumers but also ensures the longevity of the produce processing business itself.

7. Routinely Train Staff in Food Safety

Staff training forms the backbone of the food safety compliance in every produce processing business.

It’s essential that every staff member, whether in direct contact with the food or not, should be properly instructed in the core principles of food safety.

The training should not only be a onetime course but rather an ongoing process that includes up-to-date regulations and industry best practices.

These continuous training courses enable staff to identify potential risks and create appropriate responses to different situations they might encounter at work.

Providing routine training is not just to fulfill an obligation to regulation bodies, but it is a proactive effort to guarantee that the produce being processed is safe for consumption.

Incorporate food safety training into the employee onboarding process to create a uniform standard of safety awareness starting from the day they join.

Supplemental training sessions should be scheduled regularly, at least twice a year, to refresh their memories and update them on new practices and standards.

Trainings should be detailed, specific, and tailored to the tasks and roles of the employees, addressing the risks and safety measures involved in their specific roles.

In addition to general safety measures, include information in training modules about the dangers of cross-contamination, appropriate temperature control, proper sanitation practices, and pest control.

Ensure that all trainees understand the importance of committing to food safety and how their actions directly affect the final product’s quality.

Regular evaluations or quizzes should be conducted post-training to assess the effectiveness of the training and to identify areas that need improvement.

Incentivizing staff through rewards or recognition could help in instilling a sense of responsibility and commitment towards food safety.

Regular training not only maintains safety standards within the processing operation but can also help in boosting the company’s reputation as a reliable produce processor.

Always remember, training is not an expense, but an investment towards overall food safety and assurance against possible health hazards that could have grave financial implications.

In a nutshell, training in food safety must be ingrained in the work culture to assure effective food safety compliance and to provide a guarantee of safety and quality to the end consumer.

8. Regularly Evaluate Supplier Food Safety Compliance

Evaluating the food safety compliance of suppliers is an integral part of ensuring the overall safety of your produce processing operation.

Produce processors should require their suppliers to provide evidence of food safety audits and other compliance-related documentation.

This may include certificates of conformance, audit reports or third-party verification efforts.

Comprehending the food safety measures employed by suppliers is crucial for the processor to ensure the safety of the end product.

This process should be done on a regular basis as food safety standards can change over time and a supplier’s compliance level may fluctuate.

Communication is key when dealing with suppliers about food safety compliance.

Engaging them in regular dialogue helps build robust relationships and signifies the importance you place on food safety.

These discussions can foster better understanding of the supplier’s food safety protocols and provide a platform for addressing any concerns.

When evaluating suppliers, make sure you factor in their commitment to continuous improvement in food safety.

Part of this process includes assessing a supplier’s responsiveness to issue resolution and their ability to implement corrective actions.

A supplier with a robust system for rectifying non-compliances and a proactive approach to food safety signifies a valuable partner in your food safety program.

Ensure to track the performance of suppliers over time to record their food safety compliance.

Utilizing performance indicators can help identify risks and trends that might affect the safety of your produce.

Remember, a supplier’s non-compliance can potentially put your produce and consumers at risk and damage your business reputation.

Therefore, developing comprehensive procedures for evaluating supplier food safety compliance is a must for every produce processor.

These may involve conducting supplier audits, reviewing safety certificates and ensuring the supplier maintains a strong food safety culture.

9. Use Clean, Suitable Packaging Materials

In the process of produce processing, one of the significant food safety compliance tips is to always use clean, appropriate packaging materials.

Using unsuitable or impure packaging materials may lead to cross-contamination of the produce, potentially causing serious health risks.

The packaging materials should be clean and devoid of any contaminants that could affect the safety and nutrition value of the produce.

This entails that after each use, all packaging materials should be thoroughly sanitized before they are used again for packaging.

Additionally, it’s highly recommended that the packaging materials be made of food-grade materials.

Food-grade materials pose no threat to the health of the consumer and ensures that the nutritional content of the produce is not compromised.

A variety of materials can be used as packaging such as plastic, paper, glass, or metal, provided they are specifically designed for food packaging and are compliant with food safety regulations.

These regulations dictate that packaging materials must not transfer their constituents into the food in quantities that could endanger consumer health, change composition of the food in unacceptable ways or deteriorate the taste and smell of the food products.

Additionally, packaging materials should be properly stored to prevent exposure to contaminants.

This can be achieved by storing them in a dry, clean location, away from chemicals or other materials that could potentially contaminate them.

Besides cleanliness and utility, it’s also very imperative to consider the environmental impact of the used packaging materials.

Produce processors should opt for biodegradable or recyclable packaging materials where possible to lessen the environmental impact of packaging waste.

Implementing these best practices in handling and choosing packaging materials can significantly improve the quality and safety of the produce being processed.

Moreover, using clean, suitable packaging materials not only ensures compliance with food safety standards but also boosts consumer confidence in the safety and quality of your products.

In summary, the use of clean, adequate packaging materials plays a vital role in maintaining the integrity and safety of processed produce.

It’s a key element in food safety compliance and should not be taken lightly by produce processors.

10. Conduct periodic food safety audits.

One of the most effective ways to ensure food safety compliance is through the conduct of regular food safety audits.

These audits are essential in identifying potential risks and hazards in the food production process that could compromise the safety of the produce.

Food safety audits involve a detailed assessment of both the processes and the outcomes of your food safety systems.

The objective is to ensure compliance with food safety standards and regulations, as well as check that the procedures put in place are working effectively.

Several components typically come under scrutiny during such audits, and its comprehensiveness hinges on the thorough examination of these elements.

Audits involve reviewing aspects such as cleanliness, sanitization, worker hygiene and adherence to safety protocols amongst other areas.

The scope of these audits also extends to include the review of suppliers and sourcing processes to ensure that all inputs into the food production process also adhere to the necessary safety standards.

Depending on the scale of operations and the nature of the produce, these food safety audits may be carried out monthly, quarterly or annually.

However, regardless of frequency, consistency is key.

Regular and consistent audits help identify vulnerability and problems early before they escalate into significant health hazards.

It’s also important to employ a qualified and experienced auditor to conduct these assessments.

These individuals are trained to spot problem areas and make recommendations for necessary improvements, thus enhancing overall safety compliance.

Upon completion of the audit, findings and recommendations are usually compiled into a report for review by management.

This is then followed by an action plan to address highlighted areas, bolstering your commitment to food safety compliance.

Consider regular food safety audits as a vital part of your produce processing operations.

By implementing strict protocols, regular evaluations, and heeding the advice of professional auditors, you can contribute to keeping the food supply chain safe and trusted.

The Bottom Line

sentences long.

Following the precautionary measures and steps outlined in this article, particularly in regards to sanitizing equipment, employee health, and training, can help to significantly decrease the likelihood of foodborne illness outbreaks.

Proper cold storage, pest control activities, and suitable packaging procedures also contribute immensely to creation of a safer and more reliable food supply chain.

Additionally, implementing regular audits and supplier evaluations plays a vital role in maintaining a standard of excellence.

Thus, maintaining food safety is a continuous, multifaceted process that requires due diligence at every stage of handling and processing.