Within the bustling environment of produce processing facilities, maintaining optimal sanitation standards is imperative.

This is not solely about complying with regulations; it forms the backbone of food safety and product quality.

Lapses in the hygiene protocol could lead to product contamination, leading to severe repercussions for both consumers and the business.

As such, it’s essential to have a robust sanitation process in place.

This article ranges from the intricacies of sanitation equipment to the training of personnel.

Dive into this detailed analysis and guide that aims to equip you with the knowledge and tips to enhance your facility’s sanitation protocol and practices.

Sanitation Best Practices For Produce Processing Facilities

1. Regularly clean and sanitize all equipment and surfaces.

The first step in maintaining sanitation in your produce processing facility is to ensure the regular cleaning and sanitizing of all equipment and surfaces.

This includes daily activities of wiping down surfaces and cleaning equipment that comes into contact with the produce.

Given the centrality of cleanliness in preventing food-borne illnesses, health inspections often focus intensely on these aspects.

Maintaining strict cleaning schedules not only keeps your facility sparkling clean, but it also helps to impress inspectors and build a solid reputation for hygiene among your customers.

Furthermore, cleaning and sanitizing tools and surfaces wipe out microbes and dirt, which can otherwise lead to product contamination.

Regularly cleaning and sanitizing equipment and surfaces can considerably reduce the risk of product contamination and other imaginable worst-case scenarios.

Therefore, following a stringent cleaning and sanitation protocol is nothing less than a must for running a successful produce processing facility.

It’s worth noting that the type of produce you’re processing could also dictate your sanitation needs.

For instance, soft fruits like berries require gentler handling and minimal contact with equipment, while root vegetables may need vigorous washing to remove soil and debris.

All this intricate detailing underscores the importance of having a sophisticated knowledge of specific cleaning products and techniques suitable for the produce in question.

Also, you can’t overlook the significance of educating your workforce about the criticalness of cleanliness.

Yes, cleanliness is a team effort, and all employees must be aware of their role in maintaining the facility’s cleanliness and preventing foodborne illnesses.

The cornerstone of cleanliness is an explicit, detailed cleaning plan that’s known to all employees.

Such a plan spells out the intensity and frequency of the cleaning protocols, identifies who’s responsible for what, and provides a checklist for ensuring all tasks are completed thoroughly and correctly.

Additionally, conducting consistent audits to verify adherence to sanitation standards can aid untold benefits.

These audits allow you to spot any hitches in the cleaning process and make the necessary adjustments in real-time, thereby helping to maintain your facility at the pinnacle of cleanliness.

So, don’t hesitate, and buckle up to inculcate a culture that prioritizes cleanliness and rewards consistent adherence to sanitation standards in your produce processing facility.

2. Enforce strict hand hygiene among workers

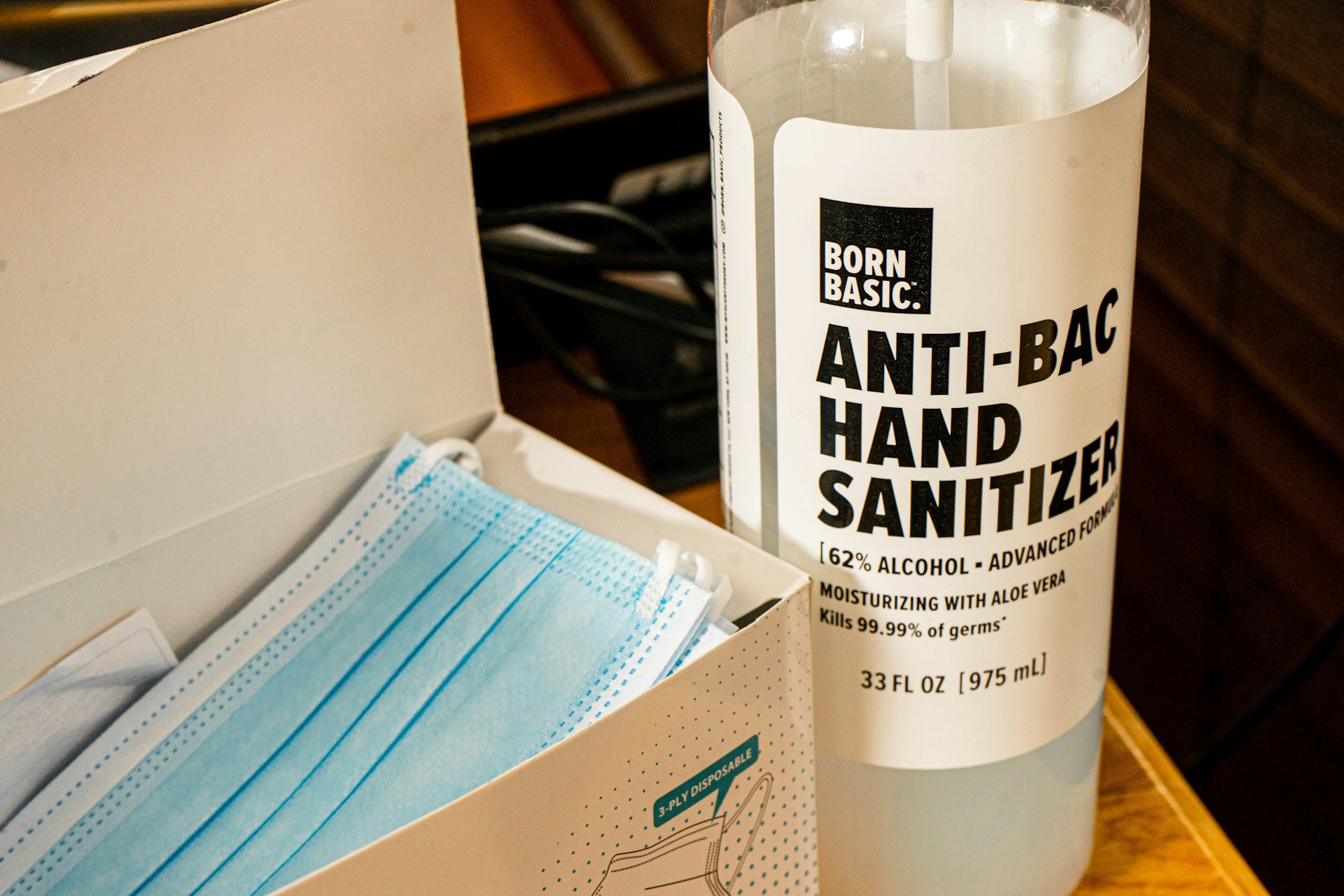

Enforcing strict hand hygiene among workers is a crucial aspect of maintaining sanitation in produce processing facilities.

Workers should be educated and regularly reminded about the importance of hand hygiene in preventing contamination.

There should be set hand-washing procedures that workers are expected to adhere to without fail.

These procedures must be specific enough to include the correct technique of hand washing, use of appropriate sanitizing products, and the right timing and frequency of washing.

Any employee who does not adhere to the hand sanitation policy should be appropriately retrained or disciplined.

Periodic training and refreshers on hand hygiene can also enhance the effectiveness of the practice.

It’s also essential to make sanitation easier by providing the necessary facilities, including running water, soaps or sanitizers, and towels for drying hands.

Sink stations should be easily accessible, well-stocked, and kept clean at all times.

Hand hygiene should not stop at just washing hands; workers should also avoid touching their faces and maintain clean fingernails.

Additionally, the use of gloves should be promoted where necessary, but it is important to remember that gloves are not a substitute for proper hand washing.

Gloves should be changed regularly, especially between different tasks and if they become damaged, since bacteria can rapidly multiply in the warm, moist environment inside a worn glove.

Each worker should understand their role in maintaining the cleanliness of the entire facility by sustaining good personal hygiene and practicing strict hand hygiene.

Effective hand hygiene among workers does more than prevent the spread of disease; it further promotes the overall health of the workers, builds a culture of cleanliness, and upholds the reputation of the business.

By regularly reminding workers of the importance of hand hygiene, produce processing facilities can ensure that sanitation best practices extend beyond machinery and storage spaces to the people who work within the facility daily.

In essence, the enforcement of proper hand hygiene among workers is not just a matter of following rules but creating an environment that values cleanliness and understands the impact of hygiene on food safety.

3. Dispose waste properly to avoid contamination.

Proper waste disposal is a crucial component in the maintenance of sanitary and safe produce processing facilities.

It is not just a matter of keeping the area clean but more about limiting bacteria, pest attraction, and potential contamination of the produce.

Companies should invest in appropriate waste management equipment such as designated bins, garbage compactors, and even industrial-grade shredders.

Through enforcing proper waste disposal routines, food processing facilities can drastically reduce the risk of cross-contamination thus maintaining the quality and safety of the produce.

The methods used for waste disposal varies depending on the nature of the waste.

For organic waste products like vegetable peels or unused parts of the produce, a compost pit can be prepared.

This doesn’t just dispose of the waste properly but also helps in maintaining an environment-friendly approach by converting waste into compost.

On the other hand, for non-biodegradable and hazardous waste, these should be disposed of following the regulations set by the local environmental agency.

It’s essential to train workers on how to segregate different kinds of waste properly and to make it a part of their daily routine.

Appropriate signs and labels also help in ensuring that segregation is correctly done.

Another significant component in proper waste management is the timely removal of waste from the facility.

Not doing so might invite pests, become a source of bad odor, and in worst cases, become a breeding ground for harmful bacteria.

The facility should set a schedule for waste collection and disposal by a trusted waste management company.

Proper documentation and record keeping of waste disposal activities is also important for tracing and accountability in case of a contamination incident.

With proper waste management, not only the company adheres to sanitation practices but also contributes to a sustainable and environment-friendly operation.

4. Store Produce at Correct Temperatures

Storage temperature is a critical aspect that profoundly impacts the freshness and quality of the produce.

Proper temperature controls not only prevent the growth of harmful bacteria but also decrease the rate of natural degradation of the products.

Different types of produce often require varying ideal storage temperatures.

As such, it is pivotal to categorize similar groups of produce together in controlled environments based on their respective temperature requirements.

Unregulated or fluctuating storage temperatures can lead to rapid enzymatic reactions causing premature ripening, rotting or undesirable changes in texture and taste of produce.

Maintaining steady temperature levels reduces the risk of cross-contamination between different produce types as well.

Specific equipment like remote temperature monitoring systems could prove enormously beneficial to ensure consistent temperature regulation.

This system provides real-time data, alerts for significant temperature changes, and valid evidence to comply with food safety regulations.

In addition, having backup or emergency cooling systems can safeguard against unexpected equipment failures or power outages.

This helps avoid produce spoilage and financial losses that may result from disrupted storage conditions.

It is also worth noting that appropriate storage temperature is not only about keeping the produce cold but also about preventing freezing.

The produce should be adequately insulated from direct contact with cooling elements as freezing damages the cell structure of fruits and vegetables, causing them to become mushy upon thawing.

Further, regular inspection and maintenance of refrigeration units are required to ensure they are functioning optimally and maintaining the desired temperature and humidity ranges.

Any observed anomalies should be promptly rectified to safeguard the integrity of the produce.

Also, timely software updates for the remote temperature monitoring units and training the staff on the functioning of these units can optimize their use and efficiency.

Lastly, to ensure optimal freshness and taste, the produce should be removed from cold storage and allowed to reach room temperature just before sale or processing.

All these measures, when effectively implemented, contribute significantly towards ensuring that the produce retains its quality and is safe for consumption all the way to the point of sale, promoting the reputation and credibility of the produce processing facility.

5. Implement Pest Control Measures

Within any food processing facility, the presence of pests can have devastating consequences, with damage and contamination of produce being primary concerns.

One of the first steps in pest control is conducting a thorough inspection of the premises and facility perimeter to identify all potential entry points for pests.

A program must be devised to seal these entry points and prevent pests from gaining access to storage areas and production facilities.

Pest control isn’t only about managing the pests that have already infiltrated the premises, but also anticipating and preventing potential infestations.

Therefore, regular monitoring and early detection are crucial components of an effective pest control strategy.

Monitoring systems can include traps and detectors for different types of pests, allowing for quick identification of any issues that may arise.

In conjunction with monitoring, regular maintenance is essential to ensure that no new entry points are created and existing barriers remain effective.

Choose pest control methods depending on the type of pest, sometimes a targeted approach like using specific pesticides, is needed to address particular pests.

However, it’s important to use such treatments sparingly and in controlled situations, due to potential risks they pose to the produce and workers.

Pests can also be controlled biologically, where natural predators like birds for rodents, or insects for smaller pests, are used to maintain control over pest populations.

Remember that effective pest management isn’t a one-time solution but rather a continuous process that needs vigilant attention and consistent actions.

Training and educating staff on the importance of pest control, signs of an infestation, and proper procedures to follow when a pest is encountered also forms an important part of any successful pest control strategy.

Additionally, working with a professional pest control service can drastically improve the effectiveness of the program.

These services have the knowledge and tools necessary to handle a variety of pest situations and can offer advice and solutions tailored to the specific needs of the facility.

Ensuring that pest control measures are regularly updated and improved upon to keep up with any changes in pest behavior or other external factors is also crucial.

To summarize, pest management is a crucial aspect of sanitation best practices in a produce processing facility and should be seen as a continuous effort, rather than an isolated task to be checked off.

The Bottom Line

Upholding hygiene standards in the food production process is quintessential to ensure safety and prevent foodborne illnesses.

Regular sanitation of equipment and surfaces, along with enforced hand hygiene among workers significantly reduces the risk of cross-contamination.

Efficient waste disposal is also central to maintaining a clean environment and repel vermin.

Correct storage of produce can dramatically lower the chances of bacterial growth, while executing pest control measures contribute towards curtailing potential sources of diseases.

All these guidelines serve as a comprehensive approach to food safety, aimed at quality maintenance from production to plate.