In the world of food production, maintaining top-tier quality is not a consideration but a necessity.

Failure to prioritize safety can compromise the health of millions and can lead to significant financial losses for businesses.

Processing raw produce in accordance with stringent regulations is essential towards safeguarding public health.

This becomes imperative considering the global demand for fresh, good quality and safe produce.

It’s a complex process, fraught with potential risks.

Here, we’ll delve into effective strategies that can mitigate these dangers and ensure optimal safety in produce processing operations.

Contents

- Steps To Ensure Safety In Produce Processing Operations

- 1. Train Employees on Safety and Hygiene Procedures

- 2. Implement Regular Equipment Inspection and Maintenance

- 3. Have suitable personal protective equipment (PPE)

- 4. Monitor Temperature Control for Perishable Items

- 5. Implement pest control and wildlife deterrents

- 6. Enforce Strict Hand-Washing and Sanitizing Procedures

- 7. Implement cross-contamination prevention strategies

- 8. Regularly Sterilize All Processing Surfaces

- 9. Ensure Regular Safety and Hygiene Audits

- 10. Follow proper storage and transportation procedures

- The Bottom Line

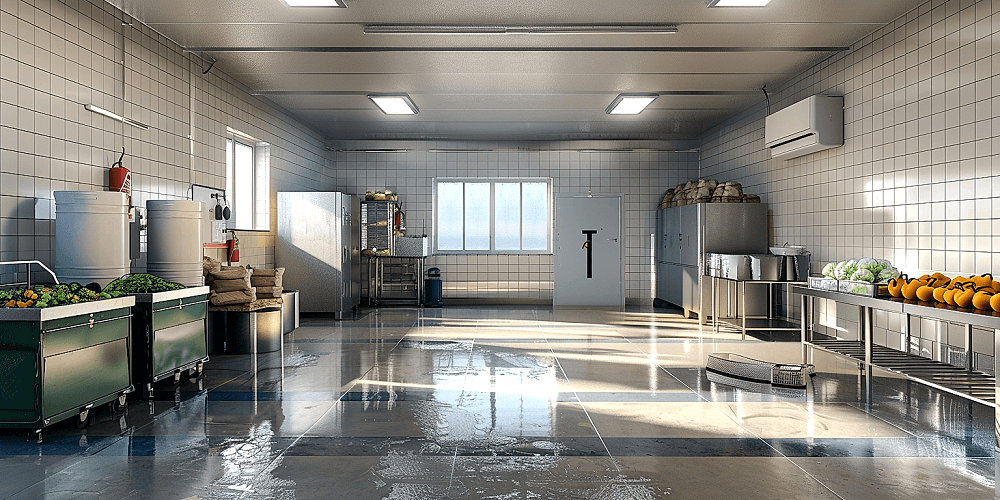

Steps To Ensure Safety In Produce Processing Operations

1. Train Employees on Safety and Hygiene Procedures

The first critical step in ensuring safety in produce processing operations is to train your employees appropriately. A well-trained staff can efficiently tackle and manage safety issues arising in a processing operation.

Begin by organizing regular safety workshops.

These workshops should be designed to educate employees about the importance of safety and hygiene in handling food.

They must be made well-aware of the potential health risks associated with working in an unsanitary environment.

Employees should be trained to understand and implement safety regulations stipulated by bodies such as the Food and Drug Administration (FDA).

The training should also include proper hygiene practices, with a large focus on regular and thorough handwashing.

These hygiene practices should extend to personal cleanliness, such as maintaining clean work attire and regularly grooming themselves.

Ambient cleanliness should also be stressed, which involves keeping workspaces clean and clear of any potential hazards.

It is important that employees are also taught to properly handle the produce, minimizing physical contact to prevent any form of cross-contamination.

Furthermore, employees should be trained in efficient waste management and disposal within the processing plant.

Regularly updating the training content and methods based on fresh data and new standard procedures is vital.

It is equally crucial for the management to assess employees’ understanding and application of the safety procedures periodically.

This assessment can be carried out through regular audits or spontaneous checks to ensure compliance.

Appropriate rewards and incentives can be provided to encourage the staff to follow the safety protocols strictly.

Ultimately, a well-trained and informed workforce plays a pivotal role in maintaining safety.

Maintaining safety and hygiene is not a one-time action but an ongoing effort, making it essential for continuous training and upskilling of employees.

Therefore, training employees effectively on safety and hygiene procedures serves as a strong foundation for maintaining good safety practices in a produce processing operation.

2. Implement Regular Equipment Inspection and Maintenance

One of the critical steps to ensure safety in produce processing operations is the implementation of regular inspection and maintenance of all processing equipment.

Machinery and equipment used in the processing of produce play an integral role in maintaining the quality and safety of the produce.

However, if these equipment are not properly serviced and inspected regularly, they can become sources of contamination.

Therefore, it’s crucial to have a comprehensive and consistent inspection schedule to prevent any mechanical failures that could result in severe safety issues.

Regular inspection and maintenance not only ensure the longevity and efficiency of the equipment, but it also upholds the safety and quality of the produce being processed.

Different equipment might require different forms of maintenance and inspection procedures.

These procedures should be aligned with the manufacturer’s guidelines and should be carried out by professionals or trained personnel.

Preventive maintenance should be prioritized over reactive maintenance as it reduces the risks of contamination and breakdowns.

This involves inspecting, cleaning, lubricating, and replacing parts as needed before a major equipment failure occurs.

This approach is cost-effective in the long run as it prevents expensive repairs and replacements.

Furthermore, having a well-maintained machine reduces downtime and improves productivity and efficiency in the processing operation.

During the inspection, attention should be given to all machine parts that come into contact with the produce.

Inconsistent temperatures, odd noises, and irregular functions are tell-tale signs of potential equipment malfunction.

The implementation of proper documentation of all inspections, maintenance procedures, and repair activities carried out on the equipment are essential.

Such a system helps monitor the performance of the machinery and identifies any recurring issues.

Overall, implementing regular equipment inspection and maintenance guarantees the safety, quality, and efficiency of the produce processing operations.

3. Have suitable personal protective equipment (PPE)

One critical safety measure for any produce processing operation is ensuring that all employees are equipped with suitable personal protective equipment (PPE).

The type and degree of PPE required will depend on the specific tasks and potential hazards associated with the given operation.

For instance, PPE can include items such as safety glasses, gloves, aprons, and specialized footwear designed to prevent slips and falls.

Other PPE can include respirators or face masks, used to prevent the inhalation of harmful dusts, toxic fumes, or particles.

PPE should be custom-fitted for each individual employee to both ensure effective protection and to allow for easy and comfortable movement.

Without well-fitted and suitable PPE, employees may be at risk for injury or illness, which can also lead to contamination of the produce

The selection of PPE should be guided by an assessment of the risks inherent in the specific produce processing operation.

Employers should also ensure that PPE is regularly inspected and maintained, and that replacements are available should any piece of equipment become damaged or worn.

To maintain an effective PPE program, it’s also essential to provide ongoing training to employees about the proper use and care of their equipment.

Employees also need to understand why the PPE is necessary and the consequences of not correctly using the equipment.

Remember, PPE is not a substitute for proper safety procedures, but rather an additional layer of protection.

Beyond the provision of PPE, safe working practices involving its use should be firmly institutionalized within the company’s culture.

Without diligence in the application of PPE, its benefits are nullified and risks to worker safety and the cleanliness of the produce process increase.

For optimal results, the PPE program should be reassessed periodically, ensuring that the equipment and training remain current with technology advances and changes in processing operations.

In essence, having suitable PPE is an essential step in ensuring overall safety in produce processing operations.

4. Monitor Temperature Control for Perishable Items

Ensuring safety in produce processing operations is highly dependent on close monitoring and controlling the temperature levels for perishable goods.

Chilling and freezing are crucial procedures in the preservation of fruits, vegetables, and other farm produce for effective processing.

There exists a critical temperature range within which produce must be kept to maintain its freshness, stave off the growth of pathogens, and reduce spoilage.

Perishable goods have their individual optimum storage temperature, which should be consistently maintained to prolong their shelf life.

For instance, a vast majority of vegetables should ideally be stored at temperatures between 0 to 10 degrees Celsius, with a relative humidity of 95 to 100 percent.

Any significant deviation from these recommended temperature ranges and the integrity of the produce may be compromised, rendering it unfit for processing.

Continuous and accurate monitoring of temperature levels within the facility is mandatory.

Both real-time and historical temperature data are extremely valuable as they allow for the identification of patterns and early detection of possible problems, ensuring that corrective measures are put into place promptly.

Automatic temperature monitoring systems should be employed, as they are both effective and efficient in recording and displaying critical temperature data.

Temperature control units should ideally be linked to alarm systems that immediately notify relevant personnel whenever there is a breach of the critical temperature range.

It is equally important that these control units undergo regular checks and maintenance to ensure that they are in the best working condition and providing accurate readings at all times.

In some cases, you may need to use different storage spaces depending on the specific temperature requirements of the perishables. Make sure that these conditions are always meticulously adhered to.

Furthermore, it may also be beneficial to use temperature-controlled transportation to maintain the requisite conditions from the point of harvest to the processing plant.

Remember, the ultimate aim here is to uphold product safety by maintaining the freshness and quality of the produce through effective temperature management.

In essence, providing a controlled storage environment via optimal temperature management is imperative for preserving the safety and quality of fresh produce during the processing operations.

5. Implement pest control and wildlife deterrents

Pest control and wildlife deterrents are an essential strategy in ensuring the safety of produce processing operations.

These pests can contribute to the spread of disease-causing organisms that can contaminate produce and pose a risk to human health.

Implementing pest control starts with a comprehensive inspection of the processing facility to identify any points of pest entry or areas that can provide them with shelter, food, and water.

This can be done in tandem with a qualified pest management professional who can provide invaluable advice on how to keep pests out and what to do if they find their way in.

Having wildlife deterrents in place is another crucial step especially in processing plants located in areas with a significant wildlife population.

Appropriate wildlife deterrent measures can involve things like fencing off the area, implementing sonic or visual predators, or even using non-lethal traps to capture and relocate any trespassing animals.

It is important to realize that deterring wildlife is not just about keeping our produce safe, but also about humanely managing the relationship between our operational needs and the natural behaviors of these animals.

Therefore, it is recommended that any implemented deterrents should be in compliance with local wildlife protection laws and regulations.

In addition to the physical deterrents, your processing operation should establish good housekeeping procedures as a proactive measure to deter pests.

This means maintaining clean and clutter-free workspaces which offer fewer attractions and hiding points for pests.

Properly stored and disposed of food waste also plays a key role in preventing pest infestations by eliminating potential food sources for them.

Weather and seasonality may also affect pest and wildlife activity, therefore ongoing monitoring and adjustment of deterrent methods are pretty necessary.

Produce processing plants should continuously invest in effective pest and wildlife control education for their staff as part of the broader strategy for ensuring safety.

This not only empowers employees but also fosters a culture of shared responsibility when it comes to safety.

Having these guidelines and measures in place is the best way to shield your agriculture undertaking from the risk of pest and wildlife contamination.

Remember, in every step of your operations safety should be your utmost priority.

6. Enforce Strict Hand-Washing and Sanitizing Procedures

Enforcing strict hand-washing and sanitizing procedures is a crucial step in ensuring safety in produce processing operations.

To maintain the highest levels of hygiene, all employees should be properly educated on the importance of these procedures and the role they play in preventing contamination.

Quality control personnel should develop comprehensive hand-washing and sanitizing protocols, which must be adhered to by all staff involved in the handling of produce.

These protocols should cover when and how hands should be washed and sanitized, including before and after handling produce, after using the restroom, and after breaks.

Preferably, automatic hand-washing stations equipped with antibacterial soap, disposable towels, and hands-free faucets should be available at strategic points across the facility, especially in production areas.

Proper hand hygiene signs should be visibly displayed at handwashing stations and throughout the facility as constant reminders for the staff.

To reiterate the importance of these procedures, continuous training and reminders should be provided to all employees, and strict adherence to these protocols should be made a requirement for continued employment.

Besides hand hygiene, the use of appropriate hand protection, such as clean gloves, should also be part of the sanitizing procedures.

However, it is important to note that gloves are not a substitute for hand washing but should be used in conjunction with this practice. Gloves should be changed frequently and also washed and sanitized as needed.

Furthermore, employees with cuts or wounds on their hands should be required to use impermeable coverings to prevent contact with produce.

Also, the management should provide ample facilities and the necessary resources to ensure that employees can easily carry out these procedures at suitable intervals or as the need arises.

The efficacy of these sanitizing procedures should also be regularly verified through inspections and microbial testing of hand swabs.

These results should then be used to improve and adjust the protocols as needed, to ensure that they remain effective.

To summarize, the enforcement of strict hand-washing and sanitizing procedures is one of the most basic, yet effective ways of preventing contamination in produce processing operations.

By committing to enforce these procedures, processing facilities can significantly reduce the risk of microbial contamination, thereby ensuring the safety and quality of their products.

7. Implement cross-contamination prevention strategies

Ensuring that your produce processing operations are safe should be a top priority, and one effective way of achieving this is to implement cross-contamination prevention strategies.

An effective cross-contamination prevention strategy should begin with proper training and education of employees regarding safe handling of produce.

Workers must also maintain good personal hygiene at all times and effectively use personal protective equipment (PPE).

It’s crucial that equipment and work surfaces are consistently cleaned and sanitized to avoid any bacteria or harmful substances that could potentially infect the produce.

In addition, it’s essential to have a good understanding of how cross-contamination can occur during the different stages of processing.

The correct sequencing of tasks in the production line is imperative to prevent cross-contamination.

Regularly rotating crops and scheduling tasks efficiently minimizes the risk of cross-contamination between different produce types.

Just as important, creating physical barriers between different processing areas can significantly reduce the likelihood of cross-contamination.

Strictly enforcing a policy of using separate tools and equipment for different produce types can also prevent cross-contamination.

Perhaps one of the most effective strategies is to implement a robust traceability system that allows for immediate action in the event of a contamination incident.

Furthermore, regularly conducting microbial testing is a reliable strategy to ensure early detection and prevention of cross-contamination.

All these strategies require an ongoing commitment to properly managing, recording, and analyzing data related to cross-contamination incidents.

In order to facilitate more effective prevention strategies, it may be beneficial to incorporate technology solutions such as automation and machine learning.

As with any safety measures, cross-contamination prevention strategies must be regularly reviewed and updated based on continual assessment of risk.

The safety of produce processing operations can be significantly improved by proactively preventing cross-contamination.

By implementing these strategies, produce processing operations can provide consumers with products that are not only fresh and high quality, but also safe.

8. Regularly Sterilize All Processing Surfaces

The importance of sterilizing all processing surfaces cannot be overstated in ensuring safety in produce processing operations.

Produce, as it undergoes processing, will inevitably be in contact with numerous surfaces, each of which presents an opportunity for contamination.

This makes sterilizing all surfaces not just a good practice, but a necessary measure for ensuring high-quality and safe produce.

Consistent sterilization of every processing surface offers a crucial line of defense against the introduction and spread of harmful pathogens.

Sterilization involves the use of heat, chemicals, ultraviolet light, or other methods to destroy harmful organisms.

It’s crucial to choose a sterilization method that is both effective and safe to use on surfaces that come into direct contact with the produce.

The frequency of sterilization will depend on the type of produce processed and the specific risks associated with it.

For instance, fruits and vegetables that grow close to the ground may carry more soil-based pathogens, necessitating more frequent sterilization.

In addition to sterilizing the processing surfaces, it’s equally important to clean the machinery used in processing.

Since these machines can harbor food particles or liquids, they may become breeding grounds for bacteria if not properly sterilized.

Sterilization should be documented to keep track of when it was done and the method used.

This documentation is helpful in case of an inspection, and it can also inform adjustments to improve the efficacy of the sterilization process.

Moreover, employees should be adequately trained on how to effectively sterilize all processing surfaces and equipment.

They need to know what techniques and products to use, the duration for sterilization, and how to verify that a surface has been properly sterilized.

Finally, never underestimate the power of a sterilization schedule.

Sticking to a schedule ensures that sterilization is not overlooked and that it is done consistently to ensure the ongoing safety of the produce.

By regularly sterilizing all processing surfaces, you significantly minimize the risk of.pathogens contaminating the produce, thus keeping the consumers safe and your business thriving.

9. Ensure Regular Safety and Hygiene Audits

When it comes to safety and hygiene in produce processing operations, regular audits play a key role.

These audits are not just box-checking exercises, but rather a critical component in maintaining the integrity of your processing operations.

They ensure that the agreed upon safety and hygiene measures are being followed at all times, preventing any looming threats to the quality and safety of the produce.

Regular audits provide an opportunity to uncover and rectify any hidden or overlooked safety and hygiene issues in the operations.

An effective safety and hygiene audit involves comprehensive inspections of all the processing operations, equipment, and facilities.

It should assess whether the current procedures and protocols are up to the mark and are being correctly executed.

Any discrepancies or lapses found should immediately be addressed with the appropriate corrective measures.

Furthermore, safety and hygiene audits should not be seen as a one-off task.

They need to be carried out periodically, to ensure that all new developments and changes in the processing operations are also following the required safety and hygiene standards.

The frequency of the audits can be determined on the basis of the nature of your produce, the scale of operations, and the risks involved.

Regardless of the frequency, these audits need to be strictly enforced and diligently followed up on.

Regular and proper documentation of the audit findings is also crucial.

This enables traceability and provides evidence of the due diligence carried out to ensure safety and hygiene.

It can also serve as an important resource for developing better safety protocols in the future.

In the end, regular safety and hygiene audits instill a culture of safety and cleanliness amongst the employees.

This fosters a sense of ownership and responsibility towards maintaining the required standards, ultimately leading to safer and more hygienic produce processing operations.

10. Follow proper storage and transportation procedures

Ensuring that produce is stored and transported correctly is integral to maintaining safety in processing operations.

Produce can be compromised if they are not handled properly during the storage and transportation phase.

There are several key factors to consider in these procedures.

Temperature control is one of these factors, as certain perishable items need to be kept at specific temperatures to prevent spoilage.

Investing in appropriate infrastructure, such as refrigerated trucks and temperature-controlled storage facilities, can mitigate the risk of product spoilage and ensures freshness and safety.

Another essential factor is the use of hygienic practices during the loading and unloading process.

Staff handling the produce should be fully informed on and committed to preserving safety and hygiene standards.

Alongside this, the vehicles and storage units utilised should be regularly cleaned and maintained to prevent potential sources of contamination.

The produce should be packaged using materials that are safe, such as food-grade plastics or sterilised containers.

These materials should not leech any harmful chemicals into the products or provide a conducive environment for microbial growth.

Another aspect of this is to avoid overpacking, which could lead to damage and increased risk of contamination.

Besides, the packaging should be suitable for the type of produce being transported, taking into account its nature, size, and delicacy.

Usage of tracking systems can ensure that any issues that emerge during transport can be quickly resolved and the quality and safety of the produce maintained.

This system can relay real-time information about the status of the transported goods and can alert the relevant parties about temperature changes, delays, or issues.

Proper planning and management are vital for effective storage and transportation procedures and can significantly reduce the risk associated with these stages of the produce processing operations.

The Bottom Line

Ensuring the absolute safety and hygiene of food in the manufacturing process are paramount for any food business looking to maintain top-notch consumer health and confidence.

This can be achieved through a multi-faceted approach.

Staff training provides a fundamental base, while routine equipment inspections, proper use of PPE, and diligent temperature controls further reinforce overall safety.

Implementing pest control measures safeguards against contamination.

Rigorous hand hygiene, effective cross-contamination prevention strategies, sterilization practices, and systematic safety audits further strengthen the barricade against possible risks.

Lastly, adhering to correct storage and transportation procedures completes the circle of a comprehensive food safety and hygiene program.

Every step weighs equally in the pursuit of ensuring the highest level of diligence in this critical aspect of the food production and distribution sector.